WE BELIEVE IN

CHALLENGING

THE STATUS QUO

COMPREHENSIVE

VALIDATION SERVICES

A KEY POINT OF DIFFERENCE: WE ARE INDEPENDENT OF THE MANUFACTURER, INSTALLER AND/OR SERVICE AGENT, AND PROVIDE ALL THE TECHNOLOGY, SYSTEMS AND TECHNICAL EXPERTISE TO GUIDE AND SUPPORT YOU IN THE VALIDATION PROCESS.

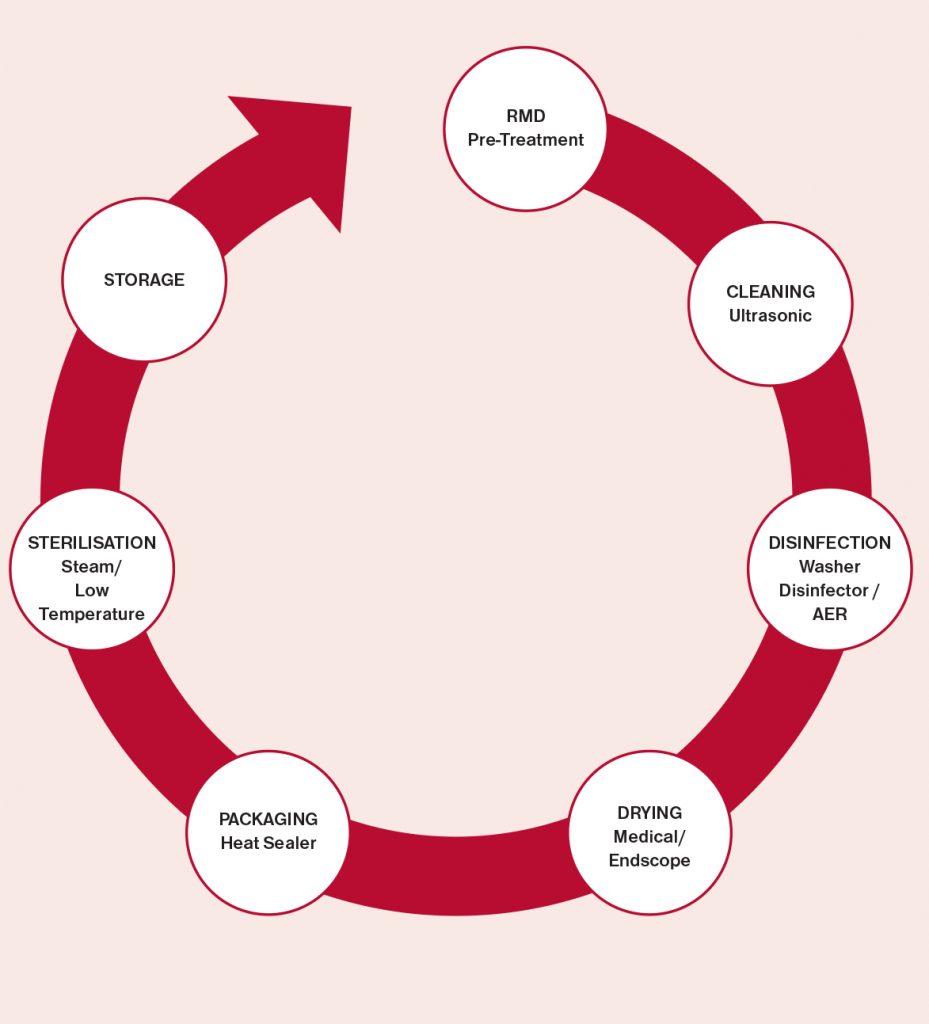

LOW TEMPERATURE (GAS PLASMA) STERILISER VALIDATION in accordance with ISO 14937 including a temperature high resolution pressure sensor that automatically detects cycles phases and exposure times in addition to micro-biological/chemical indicator analysis, sterile barrier system and drying performance.

STEAM STERILISER VALIDATION in accordance with ISO/IEC 17665 Including temperature/pressure sensor with software that automatically calculate quilibration/ penetration time, sterilisation holding time, temperature variation and banding, in addition to micro-biological/ chemical indicator analysis, sterile barrier system and drying performance. Product family classification system framework and analysis

STEAM PURITY TESTING AND STEAM GENERATOR FEEDWATER QUALITY TESTING in accordance with AS/NZS4187 (2014) Amendment 2 Table 7.4 as part of Steam Steriliser Validation Including sanitary sample cooler for steam and NATA endorsed laboratory analysis of condensed steam samples

STERILE BARRIER SYSTEM VALIDATION Automated Process Methods of Heat Sealing in accordance with ISO 11607 Including tensile testing and determination of qualified and effective seal width for a range of samples at minimum, normal and maximum temperature range

ULTRASONIC CLEANER/IRRIGATOR VALIDATION in accordance with AS 2773 Including water level, chemical dosing, water temperature, degassing performance, cleaning efficacy and ultrasonic output

WATER QUALITY TESTING of final rinse water in accordance with AS/NZS4187 (2014) Amendment 2 Table 7.2 and 7.3 as part of Washer Disinfector Validation

WASHER DISINFECTOR (THERMAL) VALIDATION in accordance with ISO/IEC 15883 including temperature

sensor on the reference load and chamber walls with software that automatically calculate actual Ao value, in addition to cleaning efficacy with process residue analysis and drying performance

ENDOSCOPE WASHER DISINFECTOR (CHEMICAL)VALIDATION in accordance with ISO/IEC 15883 including

surrogate flexible scope that allows scope channel temperature/pressure logger placement and measurement and internal cleaning efficacy indicator placement

ENDOSCOPE DRYING/STORAGE CABINET VALIDATION in accordance with EN 16442 Including air quality testing, temperature/drying performance and airborne/surface plate contamination with NATA endorsed laboratory analysis

WE HAVE DEVELOPED INNOVATIVE METHODS USING OUTSTANDING TECHNOLOGY TO PERFORM INDEPENDENT VALIDATION SERVICES